Computer Numerical Control (CNC) machines are a major component of the manufacturing industry around the world. These machines have made production and manufacturing easy and speedy. There are different types of CNC machinery for sale in the market, and it is important to understand all of them before purchasing one. All these machines are made to ensure the efficiency and productivity of the manufacturing process. The industrial procedures that took hours to complete are now done in minutes through these efficient and advanced machines.

The most common types of CNC machines used worldwide are:

- CNC Milling Machine

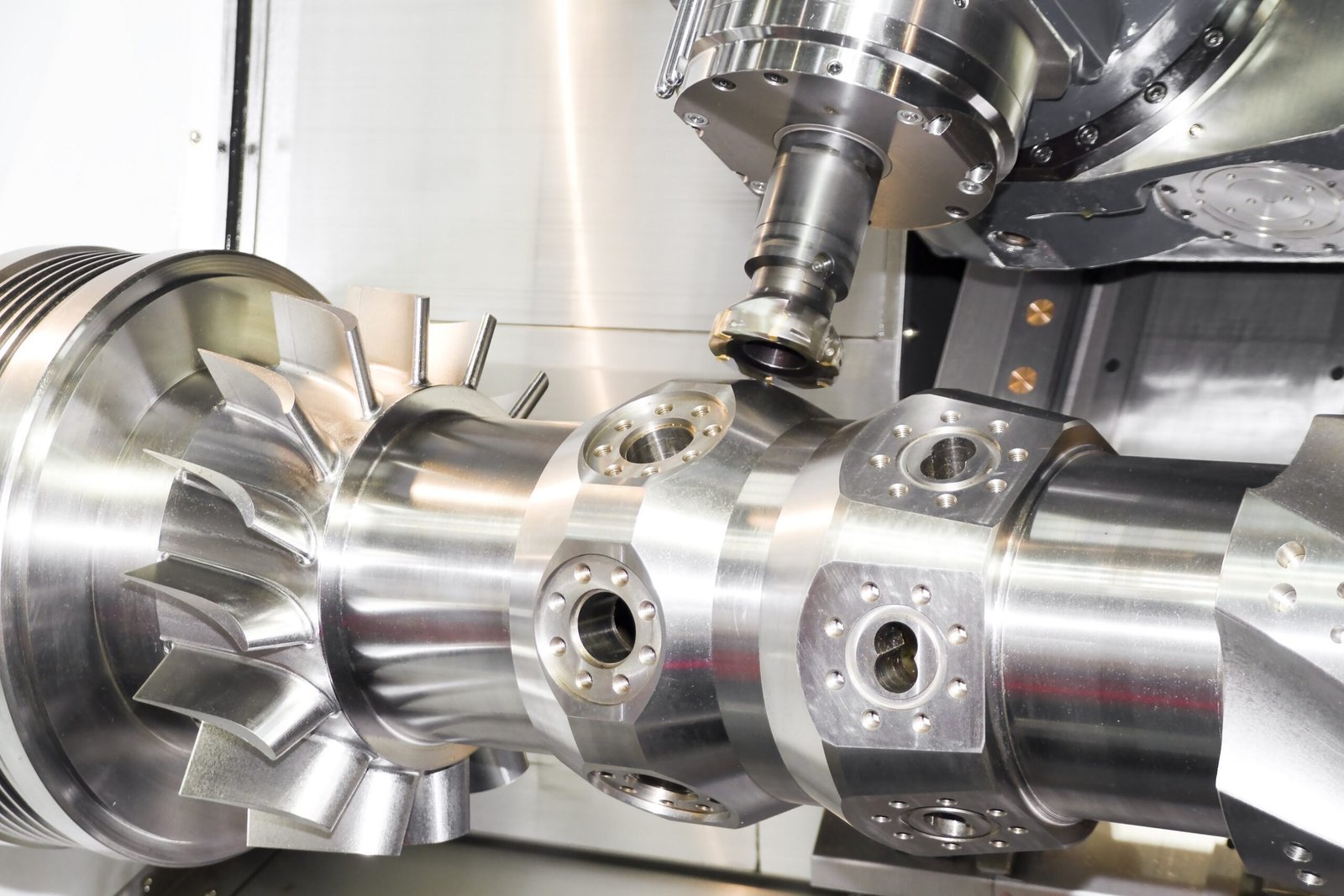

CNC milling machines are used to cut the metal or any material into many shapes by holding the material static and moving the cutter using computer-generated codes. G-code, a computer programming language, is used to understand the code written in numbers and letters. The machine moves the cutters according to input code to create a shape.

2. CNC Lathe

These machines also use G-code to cut metals into the required shape and size as the CNC milling machine. They use other languages as well. However, the difference in their functions is that lathes cut the materials while they rotate on their axis. They ensure speed and precision in their functioning.

3. CNC Router

A router works almost similar to a CNC milling machine that uses computer codes and related languages and can produce several shapes in a limited time. This CNC machinery for sales are readily available in the market. They’re used to cut wood, steel, aluminum, foam, plastic, and composite and create picture-perfect shapes.

4. CNC Plasma Cutter

Plasma cutters are used to cut heavy metals like steel. The mechanism used by this cutter uses gas and electricity to create plasma that cuts through heavy metals. The gas is blown from a nozzle at very high speed, and an electric arc that moves through the gas creates plasma, which has a temperature between 10,000 and 50,000 degrees to melts the metal.

5. CNC Laser Cutter

The laser cutters work similarly to the plasma cutter, but they use laser instead of plasma. They’re also used to cut heavy metals like steel, alloy, plastic, and wood with precision. The intensity of the laser beam depends on the density of the material under process.

6. CNC Electric Discharge Machine

Electric discharge machines use electrical sparks or discharges to create shapes within any material. The workpiece is placed between two electrodes, and a specific shape is cut down with the help of electrical discharges. A calculated amount of electric current is passed through to create the desired shape.

Where to Buy CNC machinery for sale?

It is clear that every manufacturer needs CNC machines because these machines have become one of the adamant elements of this industry. There are countless CNC machine shops in Georgia, and Flint Machine Tools is one of the many one-stop solutions for anyone who looks to buy a computerized cutting machine for their industry.